The Building Science Laboratory is used to advance the understanding of building science and proper application of HVAC equipment through research and training.

The Building Science Laboratory is used to advance the understanding of building science and proper application of HVAC equipment through research and training.

The uniqueness of this facility is the ability to vary the building airtightness, air leakage, and thermal boundary parameters in a controlled environment and evaluate their interactions with both conventional and advanced HVAC systems.

The Building Science Training Lab is a 2000 square foot building with slab-on-grade floor, concrete masonry walls, and fluted steel roof topped with lightweight concrete covered by a membrane roof surface. Designed air pathways are hidden behind the yellow louver bands located on all sides of the building. This allows the building to have different air leakage configurations to the conditioned space and separately to the ceiling cavity.

Capabilities

The Building Science Training Lab has the ability to test a variety of issues:Uncontrolled airflow—including duct leakage, restricted return air, and unbalanced exhaust air—has been identified as one of the dominant contributors to indoor air quality (IAQ), energy use, comfort, ventilation, and building degradation problems in buildings.Research need: to understand the interactions and consequences of uncontrolled airflow with various building configurations and HVAC systems.

HVAC systems are designed to deal with temperature, relative humidity, and ventilation, but are generally controlled by temperature alone. In most buildings, the ventilation need is variable while the system provides constant ventilation. As a consequence, the air handler runs continuously often producing poor dehumidification.Research need: to evaluate HVAC design/control that simultaneously controls relative humidity and ventilation energy-efficiently.

Poor indoor air quality often results from ventilation problems, pressure imbalances, or poor AC performance. Understanding uncontrolled airflows and pressure differentials is key to achieving high-performance buildings, including reduced allergy-related illnesses and workplace absenteeism.

Research need: to explore contaminant transport and generation, and how to create more productive indoor environments while minimizing toxins and allergens.

Features

AC systems

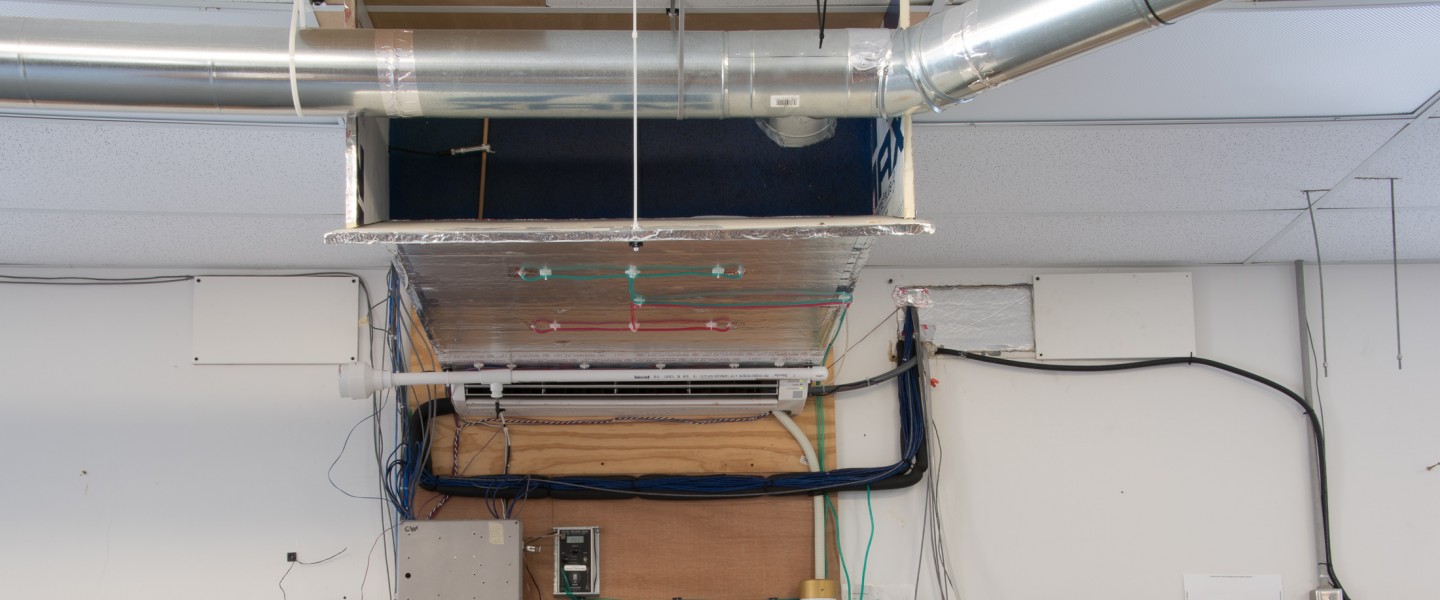

Two independent AC duct work systems of different capacity, and the ability to install split systems, roof-top package units, advanced dehumidification systems, and various control/operation designs.

Air distribution system

Ceiling

The ability to vary ceiling space ventilation, the location of the insulation (roof versus ceiling), and the airtightness of the ceiling.

Building envelope

The ability to vary building envelope leakiness by means of operable vents along the perimeter of the building, above the ceiling, and in the occupied space.

Removable wall section

This feature allows evaluation of various exterior wall assemblies.

Ventilation

The ability to change building ventilation rates and pressure differentials by varying outdoor air, exhaust air, and make-up air systems. Commercial kitchen exhaust and make-up air are controlled by VFD allowing evaluation of impacts of capture efficiency and unbalanced exhaust air under different scenarios.

Building type

This facility allows simulation of various building types, including office, retail, restaurant, assembly, as well as high-mass residential construction.

Data acquisition

Recording temperatures, humidity, air flow, and pressure in soil, slab, walls, occupied space, ceiling space, and roof, plus power sub-metering, AC condensate, and heat flux.

Training

This facility is ideally suited to hands-on building science and HVAC systems training. In addition to housing the training, it serves as a “live” training model.

Trainees will see in real time the pressure and air flow response of the building as airflow rates, barriers to flow, and pathways to flow are changed at the turn of a switch. Training topics well suited to this facility include:

- Building science fundamentals

- Energy and IAQ diagnostic

- Methods and tools

- Energy rating programs

- Ventilation system design and controls

- HVAC system design fundamentals

Research

The design of this building has the flexibility to address a wide range of issues, including:

- Interaction of uncontrolled air flows with building envelope and HVAC design variations

- Uncontrolled airflow variations

- Pressure imbalances

- Moisture control

- Indoor air quality

- Duct leakage

- Duct system design

- Building airtightness

- Building air boundaries

- Ventilation rates

- HVAC design/control