Photovoltaic modules degrade over time as they are exposed to the elements. While they are exceptionally durable—as shown by the 60-year-old modules that are still producing power and 30-year power production warranties that are becoming more commonplace—there is always room for improvement. Technology continues to improve as researchers study how it fails and take steps toward ameliorating the causes.

At FSEC, we work with academic and industry collaborators to study how modules of different technologies degrade. Not only do we study modules that have been in the field, but also degraded via accelerated age testing.

Accelerated Age Testing

Accelerated age testing exposes modules to environmental stressors that are as severe or more severe than what is experienced in the field. These tests are designed to simulate environmental conditions without requiring years of outdoor exposure. Accelerated age testing induces failures that would realistically occur in the field.

FSEC is capable of both static and cyclic mechanical load testing, in which positive or negative pressure is applied to the back of the photovoltaic panel. FSEC also works with collaborators to study the effects of other accelerated condition testing, such as:

- humidity freeze (module is put in a chamber with very high humidity and in freezing temperatures)

- thermal cycling (-40 to +85° C temperature changes), and

- damp heat (85% relative humidity at 85° C).

Inducing Field Failures

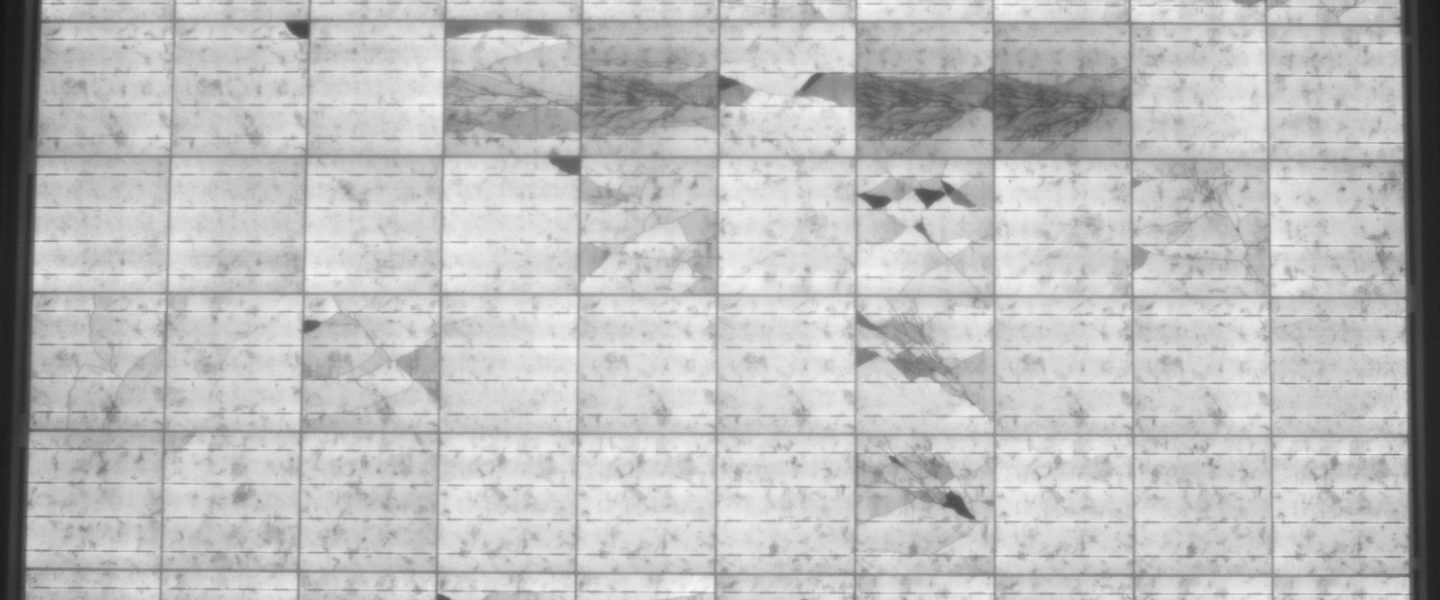

Failures are induced in modules to study how their performance changes. Inducing failures in the field reduces the time necessary to wait for failures to naturally occur. It also mitigates the need for finding data corresponding to specific failure modes. At FSEC, we have induced soiling, interconnection failures, crack formation and opening, external resistive loads, and high voltage conditions for studying potential induced degradation. Studying how these conditions impact performance gives insight into what aspects of module design need to be optimized.

Studying interconnection failures, which can occur in the field via corrosion and solder joint failure, has revealed the importance of having multiple busbars on resilience. Studying cell cracking has shown that cracks themselves do not significantly impact performance early in the life of the module, but will present problems as years go on. Studying high voltage conditions revealed the need for high voltage module qualification tests for verifying reliability.

Years of Research: 2013-2014, 2018-Current

Sponsored by: Solar Energy Research Institute for India and the United States, U.S. Department of Energy

Suggested Publications

- Experimental Methods to Replicate Power Loss of PV Modules in the Field for the Purpose of Fault Detection Algorithm Development

- Evaluating Solar Cell Fracture as a Function of Module Mechanical Loading Conditions

- Performance variation of commercially available modules after six months of outdoor system voltage stress testing