Diamond wire sawing is expected to capture 90% market share for photovoltaic monocrystalline silicon wafering by 2020. An analysis of the cost of ownership reveals that the diamond wire consumption is the biggest cost driver. In this research project, the goal is to understand why and how the diamond wire breaks and wears in order to improve its durability.

Sponsored by: U.S. Department of Energy (SunShot PVMI)

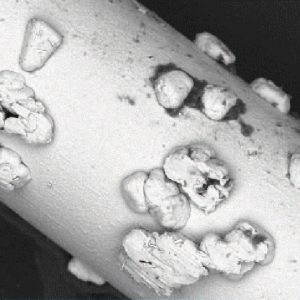

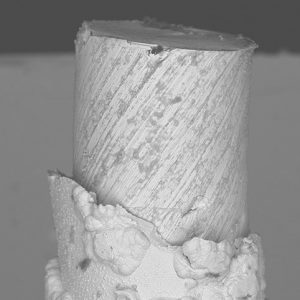

New vs. Used Diamond Wire

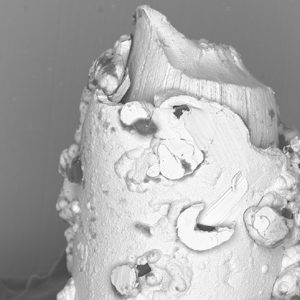

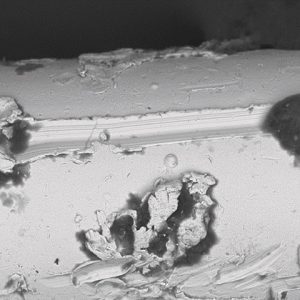

Failure Modes

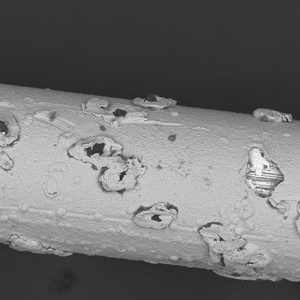

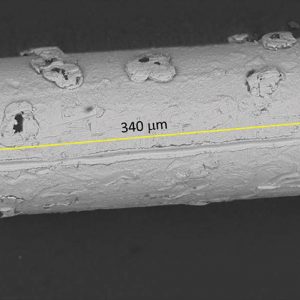

Wear Mechanisms

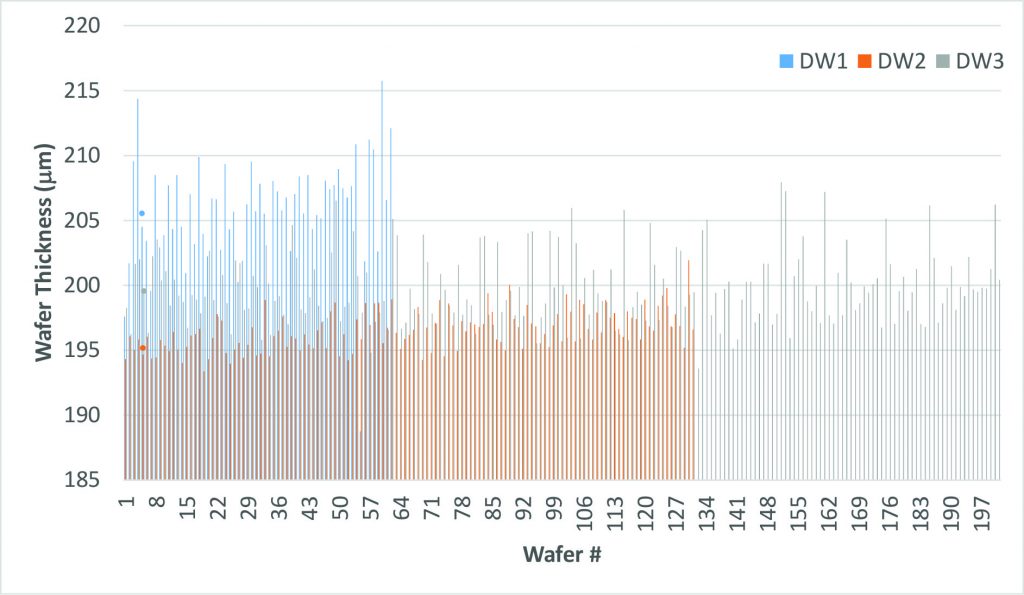

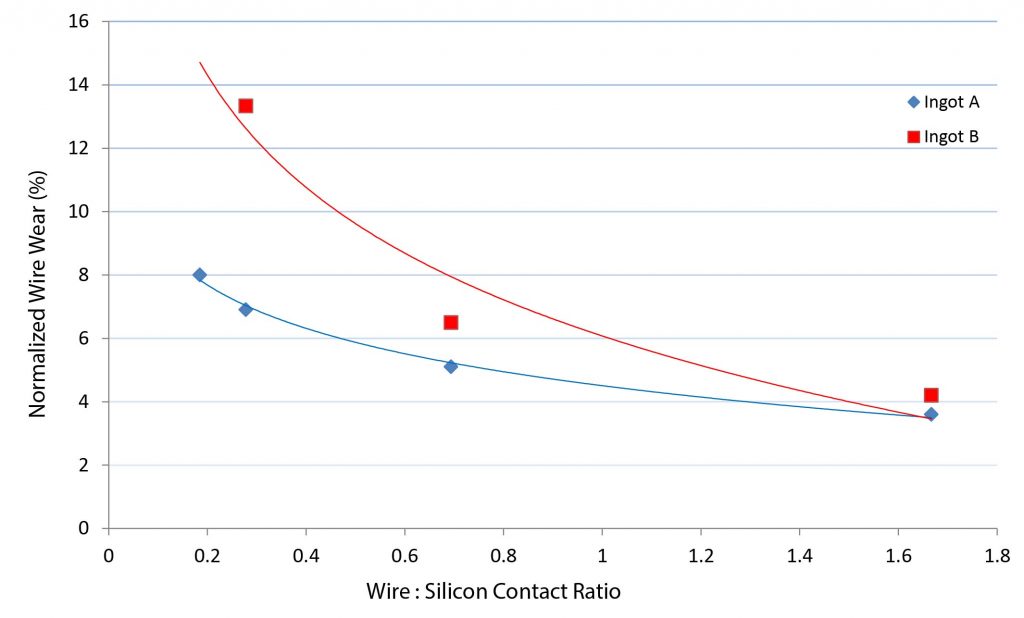

Wear Rates